Excellent service

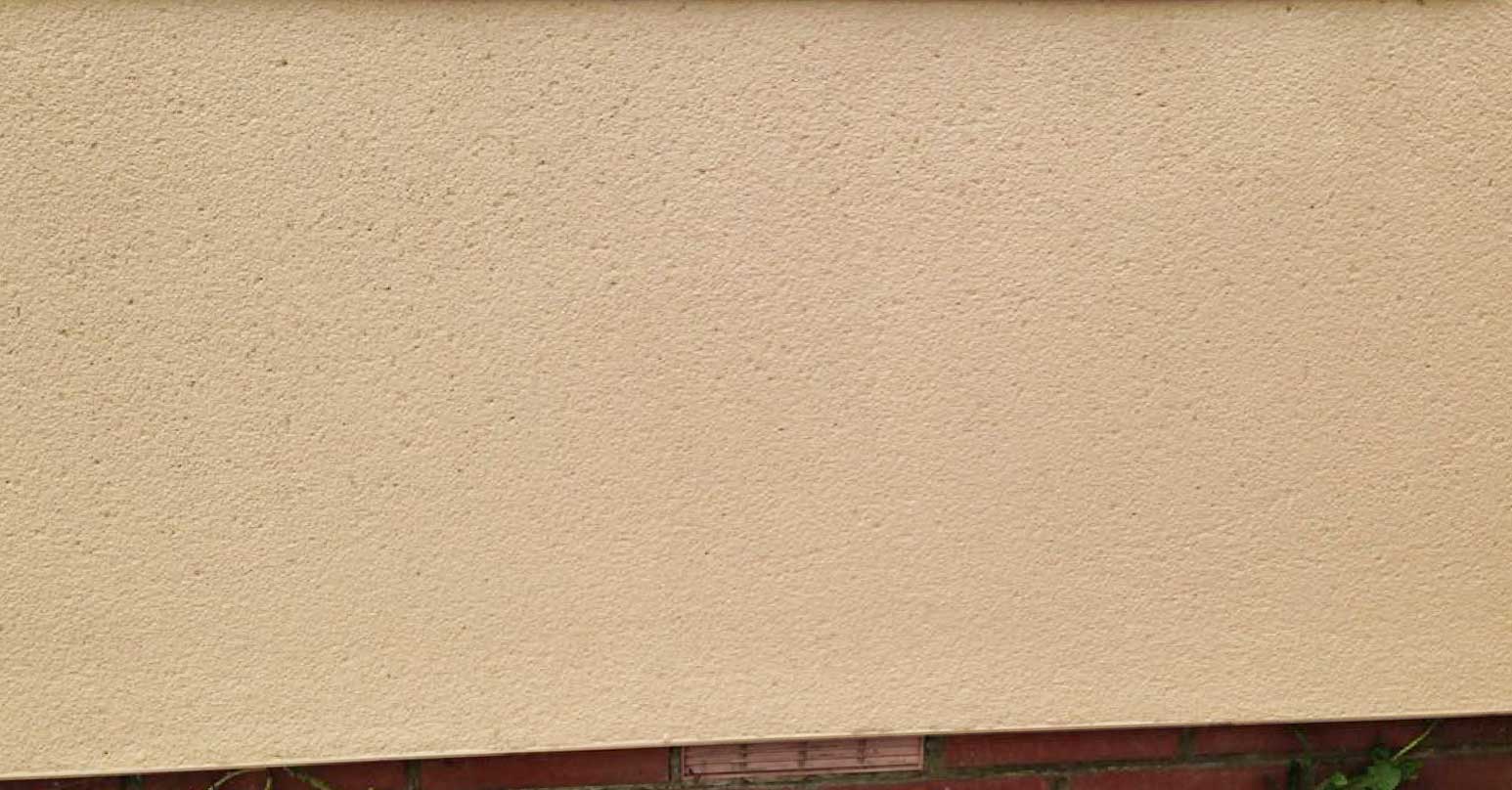

Our whole experience with this service was seemless. From the administrative side of arranging the quote and to the repair itself. Jenny was really responsive to any email I sent and the work by Paul was fantastic- you would never think there had been a problem. Would highly recommend.

Feefo Review | 2023 | R Kundi